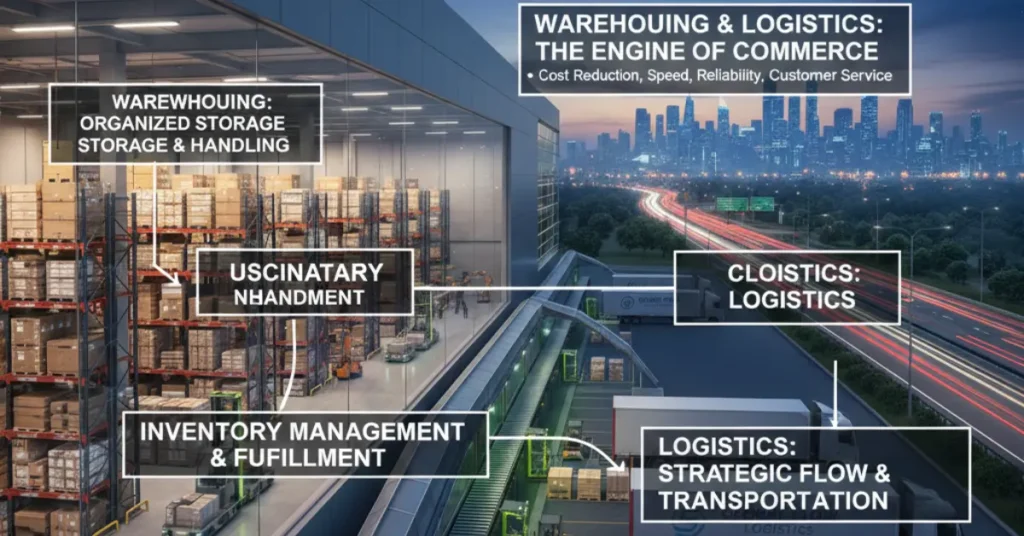

Warehousing and Logistics :The Engine of Commerce

What is Warehousing and Logistics? The modern global economy is characterized by a rapid, continuous flow of goods from manufacturer to consumer. At the very heart of this intricate mechanism are two inseparable and fundamental disciplines: warehousing and logistics. While many people use these terms interchangeably, truly successful businesses understand their unique roles and symbiotic relationship. Mastering this partnership is key to winning in the global marketplace.

This article takes a deep dive into the integrated world of warehousing and logistics, detailing their core functions, explaining why they are different yet strategically interdependent, and outlining the profound competitive benefits that their synchronization brings to any modern business.

Defining the Supply Chain’s Cornerstones

To truly appreciate the combined impact of this powerhouse duo, we must first clearly define each component. They are the two most crucial facets of the overall supply chain management (SCM).

Logistics: The Grand Strategy of Movement

Think of logistics as the strategic plan. It’s the process of figuring out, carrying out, and controlling the efficient, effective forward and reverse flow and storage of goods, services, and related information. The goal? To meet the customer’s needs, from the initial raw material acquisition right up to the final delivery.

Essentially, logistics deals with movement and coordination. It involves complex activities like managing transportation (air, sea, road), material handling, selecting packaging, ensuring security, and, perhaps most importantly, managing the flow of data that connects all these moving parts. Logistics is the strategic brain, ensuring that the right product arrives at the right place, at the perfect time, in pristine condition, and at the lowest possible cost.

Warehousing: The Organized Hub of Inventory

Warehousing, on the other hand, is the specialized, hands-on activity within logistics focused on the effective storage, organization, and efficient physical handling of goods and inventory. We often confuse the activity (“warehousing”) with the place (“warehouse”). While the warehouse is just the building, warehousing is the process that happens inside it.

This process is far more complex than simply stacking boxes. It involves mission-critical tasks: meticulously managing stock levels, guaranteeing optimal product safety and maintenance, and rapidly preparing those goods for their next journey. Warehousing is the indispensable pause point in the supply chain where significant value is added through organization and preparation.

The Essential Difference: Flow Versus Holding Power

While intimately connected, the fundamental distinction between warehousing and logistics lies in what they are primarily trying to accomplish: movement versus stillness.

| Aspect | Logistics Management (Macro-Strategy) | Warehousing Management (Micro-Execution) |

| Main Focus | The Flow and movement of products (Transportation). | The Storage and physical control of products. |

| Scope | Broad, multi-location process (Part of SCM). | Narrow, single-location operation (An internal activity within Logistics). |

| Core Goal | To optimize movement, control transport spending, and meet customer deadlines. | To maximize space, protect goods, and process stock for fast dispatch. |

| Key Actions | Route planning, carrier sourcing, IT systems integration, supply chain visibility. | Receiving, putaway, physical inventory counting, picking, packing, facility maintenance. |

You could say that logistics is focused on the journey, while warehousing is focused on the pit stop. The key is that successful businesses treat them as interdependent parts of a larger machine.

The Symbiotic Power of Integrated Warehousing Logistics

The concepts of warehousing and logistics are truly two sides of the same operational coin. In fact, warehousing isn’t just “related” to logistics; it’s a mandatory function within a successful logistics system. The overall speed and efficiency of the logistical flow are entirely dependent on how well those warehouse nodes function.

An integrated approach, often termed warehousing logistics, recognizes that storage and movement must work in complete, technological harmony.

The Warehouse as a Strategic Weapon

In today’s competitive environment, a warehouse is much more than a shed; it’s a strategic distribution hub. When logistics and warehousing teams collaborate closely, they allow companies to:

- Cut Shipping Times and Expenses: By placing goods in multiple, strategically located distribution centers closer to the final consumers, logistics teams can instantly route orders to the nearest facility. This dramatically shortens the last-mile delivery leg, leading to faster shipping times and a huge reduction in transportation costs.

- Enable Value-Added Services: The warehouse is the ideal place for the logistics process to pause while value is added. This includes customization, kitting, specific labeling, or final assembly—all crucial tasks that get the goods ready for their specific logistical journey to the customer.

- Ensure Stability and Resilience: Warehousing facilities hold crucial buffer stock. This allows the wider logistics network to easily absorb sudden shocks and disruptions, whether they come from geopolitical issues, supplier failures, or unexpected demand surges.

The Core Processes: Inside Warehousing Logistics

The operational triumph of integrated warehousing and logistics relies on a sequence of vital steps that transforms static inventory into dynamic, ready-to-ship orders.

1. Receiving

This is where the entire process kicks off. Goods arrive from suppliers, and the logistics team’s plan (inbound logistics) is handed off to the warehouse staff. Here, the team meticulously checks the quality and quantity of the incoming items against the purchase order. Let’s be honest: an error at this stage can spiral and cause chaos throughout the entire supply chain.

2. Putaway and Storage

After verification, the items are moved from the receiving dock to their home location. The warehousing logistics team uses cutting-edge tools like Warehouse Management Systems (WMS) to decide the best spot, guaranteeing maximum space utilization and ensuring items are grouped logically for super-fast retrieval later. Specialized setups, like those offering cold storage logistics, are vital for maintaining product quality and extending shelf life.

3. Inventory Management

This function is the absolute nerve center of the warehouse. It constantly tracks, measures, and updates inventory levels in real-time. This provides the crucial visibility the larger logistics function needs to make smart decisions—knowing when to reorder, spotting slow sellers, and avoiding the severe costs associated with having too much or too little stock. Optimized inventory management is a direct, measurable benefit of strong integration between warehousing and logistics.

4. Order Fulfillment (Picking, Packing, and Shipping)

This is the mission-critical stage where static inventory transforms into a dynamic outbound shipment.

- Picking: Staff retrieve the ordered items from their storage locations. This single task often eats up the majority of a warehouse’s labor resources. Efficiency is key, and teams use advanced techniques like automated systems or zone picking to save time.

- Packing: The picked items are confirmed, securely packaged, and prepared for transit. From a logistics standpoint, this involves precise weighing, calculating volume, and printing the carrier-specific shipping labels (the start of transportation logistics).

- Shipping: The packaged orders are loaded onto trucks or other carriers for final delivery to the end customer. This completes the warehousing cycle and fully transitions the goods back into the transportation logistics network (outbound logistics).

The Ultimate Payoff: Competitive Advantage

A fully integrated approach to warehousing and logistics does much more than just move and store items; it creates a powerful competitive advantage that directly fuels a company’s profits and strengthens its market standing.

- Significant Cost Reduction: By ruthlessly optimizing storage space (warehousing) and efficiently consolidating transport loads (logistics), companies dramatically cut costs related to facility overhead, labor, and transportation spending.

- Elevated Customer Service: The strategic location of inventory and a rapid fulfillment process translate directly into faster, more accurate, and more reliable deliveries—the bedrock of modern customer loyalty.

- Unrivaled Inventory Visibility: Real-time tracking from the moment a product is received until it ships provides total clarity over the stock lifecycle, drastically minimizing inventory errors and business risk.

- Market Agility: Strategic warehousing allows businesses to hold necessary inventory during periods of low demand or price volatility, ensuring they can release goods to the market at optimal times for better profitability, effectively helping to stabilize market prices.

Ultimately, achieving mastery over the seamless integration of warehousing and logistics is not optional; it is essential for any entity hoping to compete, scale, and thrive in the fast-paced, complex global economy.